Forced feeding universal efficient ouerall granulator

Category:

Forced feeding universal efficient ouerall granulator

Summary:

When the filter is working, the water to be filtered enters through the water outlet, flows through the filter, enters the pipeline required by the user through the outlet for process circulation, and the particulate impurities in the water are trapped inside the filter

Key word:

Filter

Forced feeding universal efficient ouerall granulator

Filter is an indispensable device on the conveying medium pipeline, usually installed in pressure reducing valve, pressure relief valve, water level valve, square filter and other equipment of the inlet end equipment. The filter is composed of cylinder, stainless steel filter, sewage part, transmission device and electrical control part. After the water to be treated passes through the filter cartridge of the filter screen, its impurities are blocked, and when it needs to be cleaned, just take out the removable filter cartridge and reload it after treatment, so it is extremely convenient to use and maintain.When the filter is working, the water to be filtered enters through the water outlet, flows through the filter, enters the pipeline required by the user through the outlet for process circulation, and the particulate impurities in the water are trapped inside the filter.

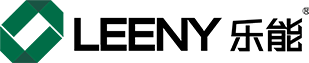

The technical filed of the present invention is unique in the world:

-

The tank chain rotates to force feed and the closed structure is unique in the world , have function of double-sided extrusion automatic dehydration.Equip with compression zone heating device during extrusion,making plasticcompletely softens and shrinks, screw wear is very low,.And it greatly improves the production efficiency.

-

Specially designed side feed at the bottom of the screw, no resistance to the feeding mode of the raw material.Both sides of the feed port can be fully opened, convenient for maintenance and can direct spray of alloy.

-

The screw design of this invention is also special, application of the theory of high-speed with high-volume prosuction equal deep-separable. No resistance to extrusion, production doubled than normal screw.

-

The design of the plasticized zone is also unique.There are many impurities in recycled plastics,after a long timeof work, it will clog on the screw,making production decline in production. But innovations in the barrel can separato and directly clean debris on the screw, and the barrel inner sleeve can also be directly replaced.. This design is suitable for a wider range of materials, Do not need to worry about the screw will be stuck and repaired.

-

The advantage of the overall model is that one screw can equip with two or three machines,directly equip two recycling step of filter without mesh,mesh size up to 100 mesh, PLC control continuous production can be automated

Previous page

None

Next page

HELLO, LEAVE YOUR THOUGHTS

A demand is the prerequisite for the establishment of cooperation and the beginning of the service.Fill out the demand form immediately and we will get in touch with you in time.